Colourful window frames with acrylcolor

Published on: 03. 03. 2016 - 9:57

Published on: 03. 03. 2016 - 9:57 Set accents in your facade with coloured window profiles. Make your house as individual as its inhabitants, or turn any building into an eye-catcher.

With acrylcolor, GEALAN offers colourful window profiles with unique qualities. The special coextrusion fuses two high-quality materials together in an unbreakable bond. The white basis form is made of PVC, and the exterior is mantled in colourful acrylic. The resulting combination shares the advantages of both materials.

The white interior surface of the profile guarantees that the window will harmonise with any room, no matter the decoration.

What is acrylcolor?

During the colouring stage of the co-extrusion process, the white PVC substructure and the coloured acrylic glass are permanently bonded with one another in one step. Fusing both of these materials produces a semi-matt, coloured outer profile surface that withstands the effects of the weather with ease.

Proven for decades

GEALAN has been co-extruding its coloured acrylcolor profiles for over 30 years. It is setting standards by using this process, because of how different it is from other common colouring processes. The result is unsurpassed colour characteristics and many years of colour fastness. Windows featuring acrylcolor profiles also satisfy the most stringent technical and functional requirements.

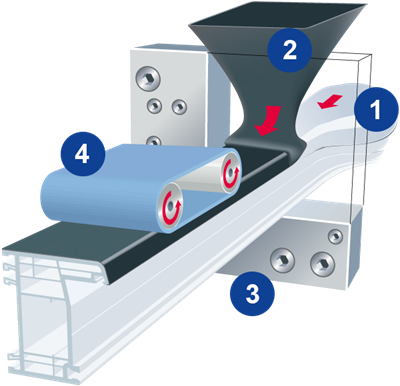

The principle of co-extrusion

During co-extrusion, the white PVC substructure and the coloured acrylic glass (PMMA) are permanently fused with one another. Acrylic glass is a high-quality product that has proven its qualities in industrial sectors such as the automotive industry (tail lights) and interior design. The vinyl profile acts as a carrier material, while the thin layer of acrylic glass is responsible for the profiles' colouring.

1 The white PVC melt is fed via the main extruder.

2 The coloured acrylic melt mass is added via a co-extruder.

3 The two liquid components are permanently bonded with one another in the co-extrusion tool.

4 To achieve a closed surface and a brilliant colour, the profile surface is polished with a grinding machine.

A one-of-a-kind surface texture

Brushing the acrylic layer not only produces a standardised grain, but also a fine, semi-matt gloss on the surface. This high-quality finish is unique on the coloured window market.

Benefits of acrylcolor

TRUE COLORS

Acrylic is particulary resistent material. Used for decades in the manufacture of cars, after years and years of exposure to atmospheric conditions, paint remains the same. Even frequent replacment of window sash in the same window frame, even after many year's it's almost impossible to tell the difference in color.

EASY MAINTENANCE

Profile windows with acrylic paints don't need much maintenance and when they do, it+s very simple. No stripping, grinding and re-applying the paint and therefore none of these costs. Those profiles reject dirt and dust and are cleaned very easly with ordinary cleaning products.

RESISTANT TO SCRATCHES

Window that are made out of acrylic paint profile have smooth, silky surface without pores. Connecting PVC and acryl under the influance of heigh temperatures gives special resistance. They are not only resistant to scratches, but also insensitive to clusters of dirt and dust.

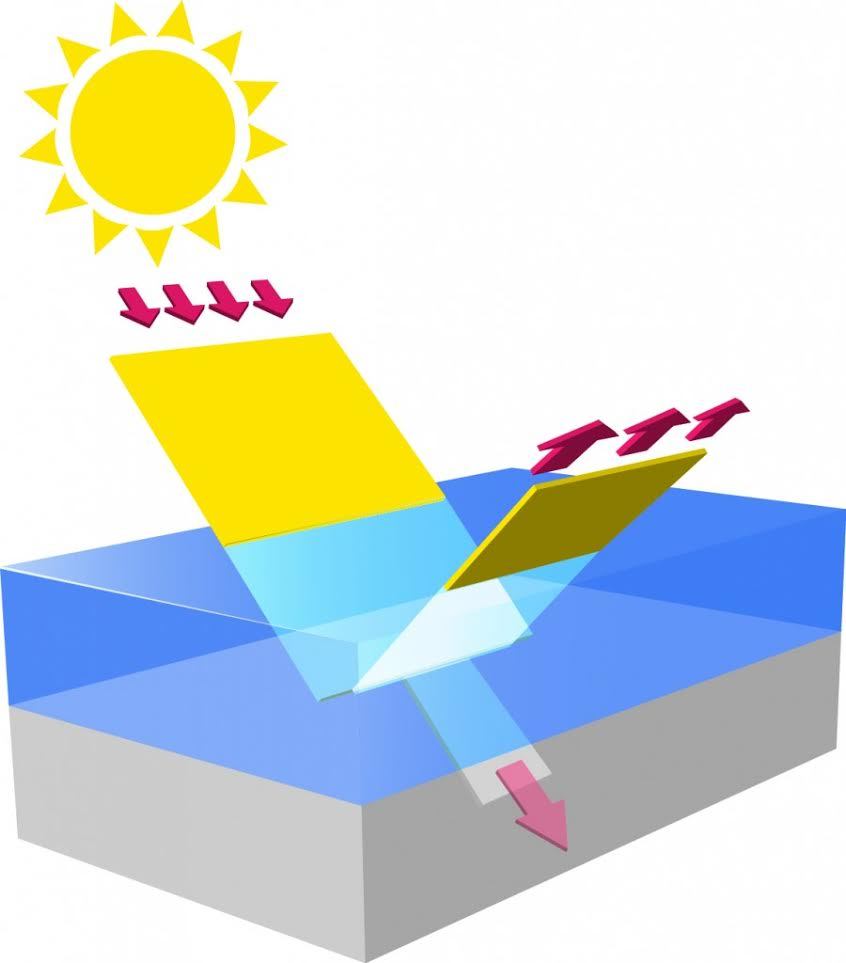

HIGH REFLECTION

Sunlight is largely reflecetd by white base layer, located beneath a layer of acrylic paint that leaks infrared rays. In this way heating of the profile is significantly reduced. Temperature differences between very dark and white windows are suprisingly small.

100% RECYCLABLE

Windows with acrylic paints are fully recyclable. Profile residues are returned in production as raw materials. Old windows are granulated and prepared for further use. The result is a very valuable material that can be reused in new products. In that way we make constant circular flow of used materials.

Photo Gallery

Black Brown 02 similar to RAL 8022

Black Brown 02 similar to RAL 8022

RAL 7015: Slate Grey

RAL 7015: Slate Grey

RAL 7016: Anthracite Grey

RAL 7016: Anthracite Grey

RAL 7040: Window Grey

RAL 7040: Window Grey

RAL 8014: Sepia Brown

RAL 8014: Sepia Brown

White Aluminium similar to RAL 9006*

White Aluminium similar to RAL 9006*

Silver similar to RAL 9007*

Silver similar to RAL 9007*

DB703*

DB703*